It was a clear, crisp Monday morning in Neuchâtel. I was about to have my first manufacture visit, to a brand I have always admired. With me was my friend, Mike Wüthrich together with Team WIS United. We weaved toward the Jura Mountains, emerging at the outskirts of La-Chaux-de-Fonds. It sure was watchmaking country as we passed by a few manufactures along the way, until we reached our destination: Le Locle – the home of Zenith.

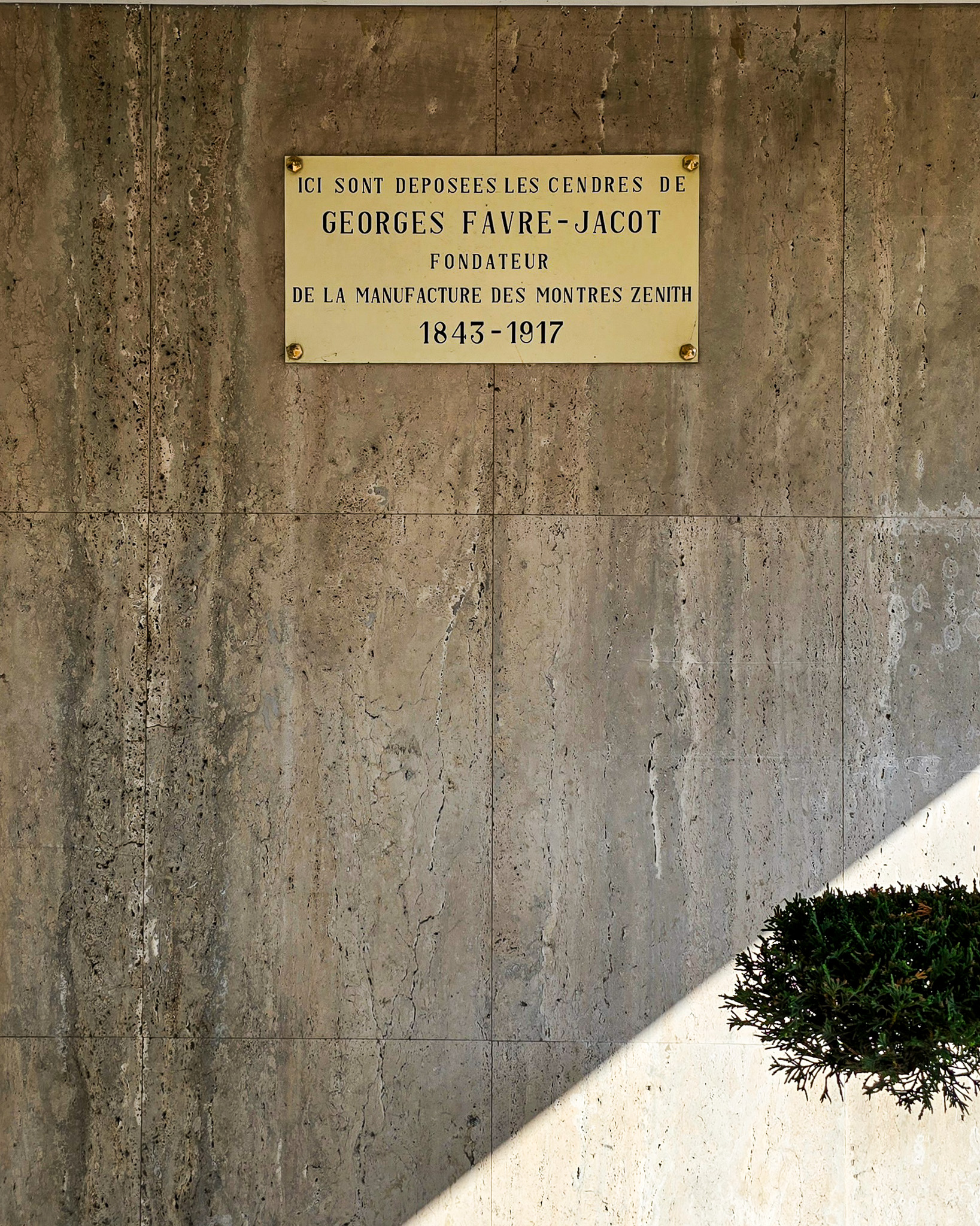

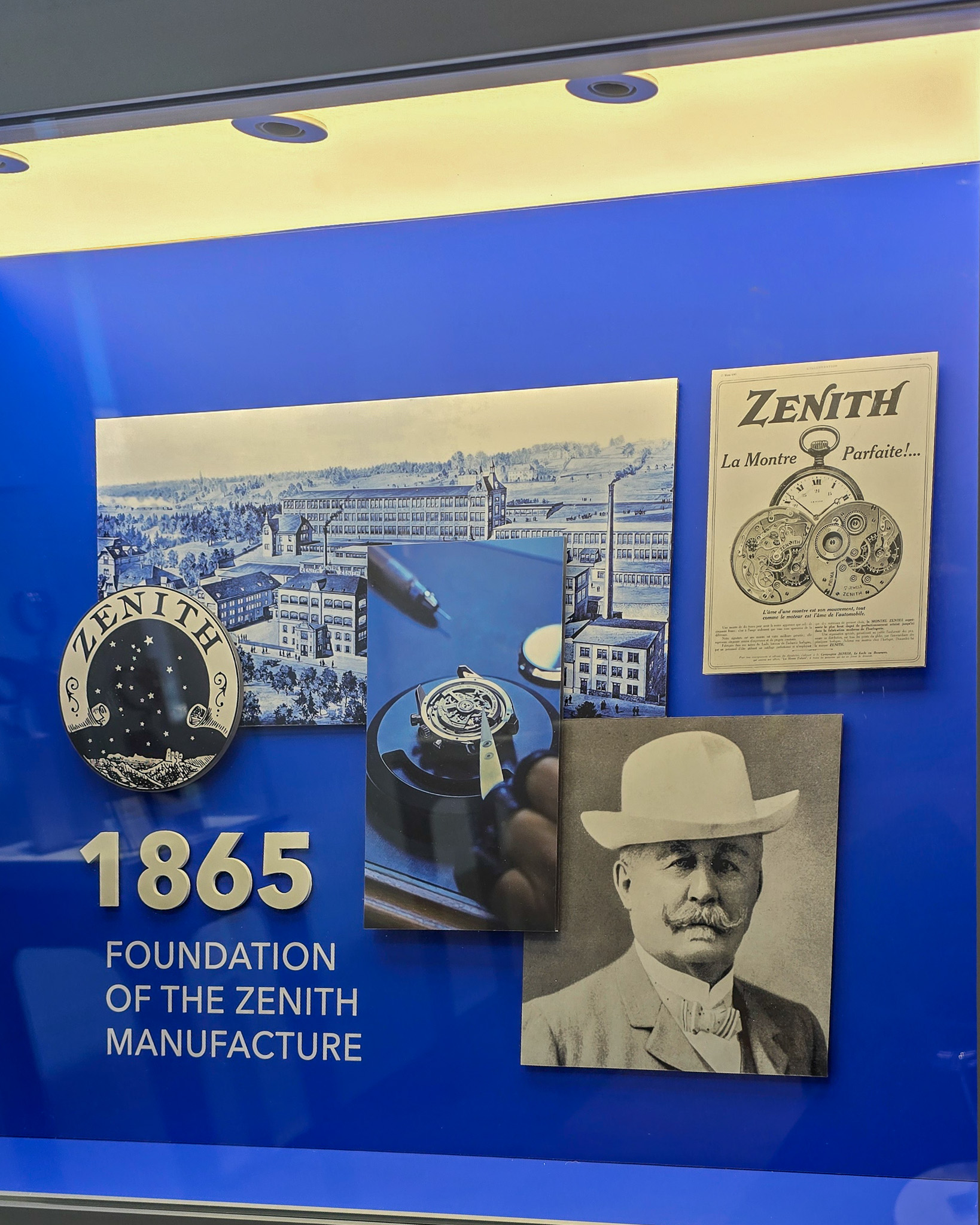

There are only a couple of heritage brands still situated in their original site since its founding, and the Zenith Manufacture is part of that esteemed group. It has been pivotal to the industry and development of the town since Georges Favret-Jacot laid the foundations of a fully in-house operation in 1865.

This manufacturing complex has been purpose-built to meet watchmaking’s processing needs then, and has continually evolved to meet the needs of the present. Placing it by the railway facilitated the transportation of raw materials into the compound. Constructing on a hillside meant each building had its fair share of natural light, thanks to its south-facing orientation. And of course, a lot of big windows, framed by beautiful red bricks, bring in all that natural illumination through the workshops. Always one for pushing things forward, the town of Le Locle was connected to the electricity grid thanks to Zenith’s manufacturing activities in 1886. Now, its roof sections have solar panels installed as it continues its efforts to being a self-sustaining & forward looking manufacture.

Upon entering its reception, our party was ushered into the showroom, which showcased all current production models as well as some key limited editions. My pick of the bunch was the Zenith Chronomaster Revival – Manufacture Edition which you can only buy new from the manufacture itself. Perhaps one day! After a briefing over espresso, we were then whisked away by our guide, the marvellous Romain Mazzilli.

R&D – Heritage meets the future

As a heritage brand, Zenith has a deep archive from which it can draw from. Being in the same place since its inception has its advantages wherein a lot of historical plans, parts and even tools have been kept, meticulously catalogued and traceable against the watch serial number.

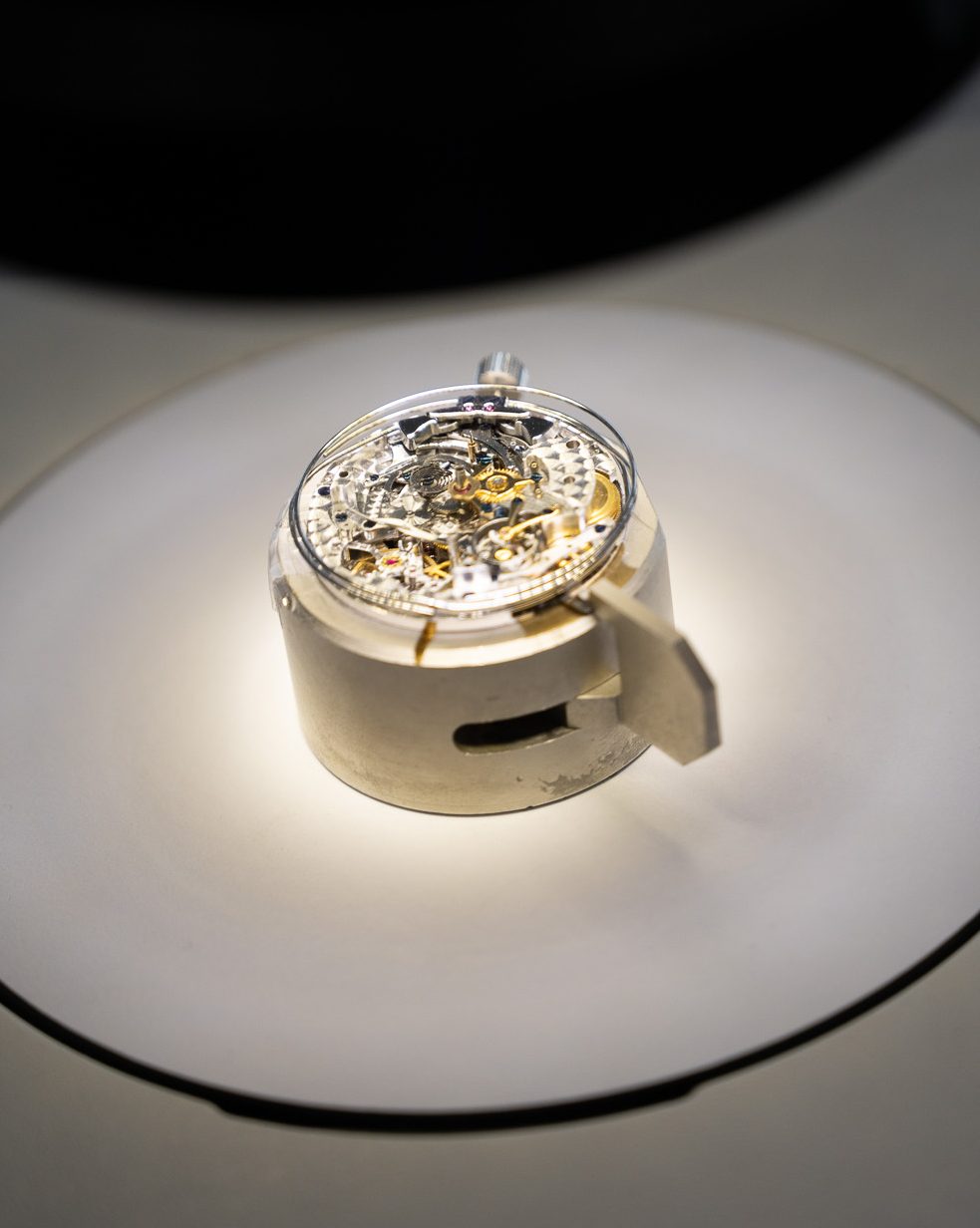

The approach to designing new pieces and looking for improvements on previous iterations have of course moved on with the times, thanks to computer modelling and 3D printing technologies. Starting at the R&D section, we got to see how the team looks to the past to create something new. It is also where I first got to handle a Christophe Colomb Hurricane, with its distinctive sapphire bubble housing its gyroscopic escapement. It was interesting to hear the approach taken to further its development as the technology evolved into the Defy Zero G we know today, as miniturisation became possible for this horological marvel.

Of components and machines

Walking through the component workshop gave a deep sense of history. It’s an interesting mix of the old and new, showing how both can co-exist. The original pillars from 1865 had pictures of what the workshop looked like at the time. Images of old equipment and a workforce from a different era amidst a collection of modern machinery. One thing I never quite appreciated until I saw rows and rows of it, is the historic use of brass for base plates, thanks to its ductility and malleability. This ancient alloy of copper and zinc, known for its golden colour and corrosion resistance, has been a mainstay in components that require a lot of milling and shaping.

Leaving the hums of the ground floor, we pass by the quality control section where manufactured parts are checked. Spools of steel welcomed us amongst shelves of stamps when we got to the prototyping section. True to its in-house, vertically integrated model, Zenith manufactures its own stamping tools. Solid cast iron pieces, each designed to generate one or several components at each press cycle. We were given a demonstration of how stamps make impressions of components on both sides of material, with each face distinct as required by the component plans.

As we pass by the decoration section, we see that traditional hand finishing still has a place in Zenith. There’s just something about the human touch and the expertise gained in its long history that simply cannot be replicated. Or perhaps any attempt to do so thus far, simply is not as good. From base plates to bridges, escapements to rotors, it is good to see that expert hands, crafting minds and the diligence which represents some of the 80 different fields of expertise within the complex are still at the heart of production, despite its mechanised army.

When it all comes together

Arriving on the top floor, and walking over some sticky mats to ensure we reduce any dirt and debris, we prepare to go into our next destination. The lab gowns have been waiting in anticipation, we’ve arrived at the watch assembly section.

Gowns and shoe covers on, we enter to a full floor dedicated to putting every Zenith timepiece together. The space is designed to minimise contamination of dust and particles hence having all assembly activities done in the same area. But another benefit it brings is that communication between each segment is easier due to their proximity. The flow of the floor is organised sequentially, starting with the first section which is dedicated to component preparation & putting in jewels. Whilst the majority of the rubies are placed with the assistance of machines, there are still some components that will need to be jewelled by hand. Meticulously placed, it relies on the human touch to know if it has been affixed with the right tolerance.

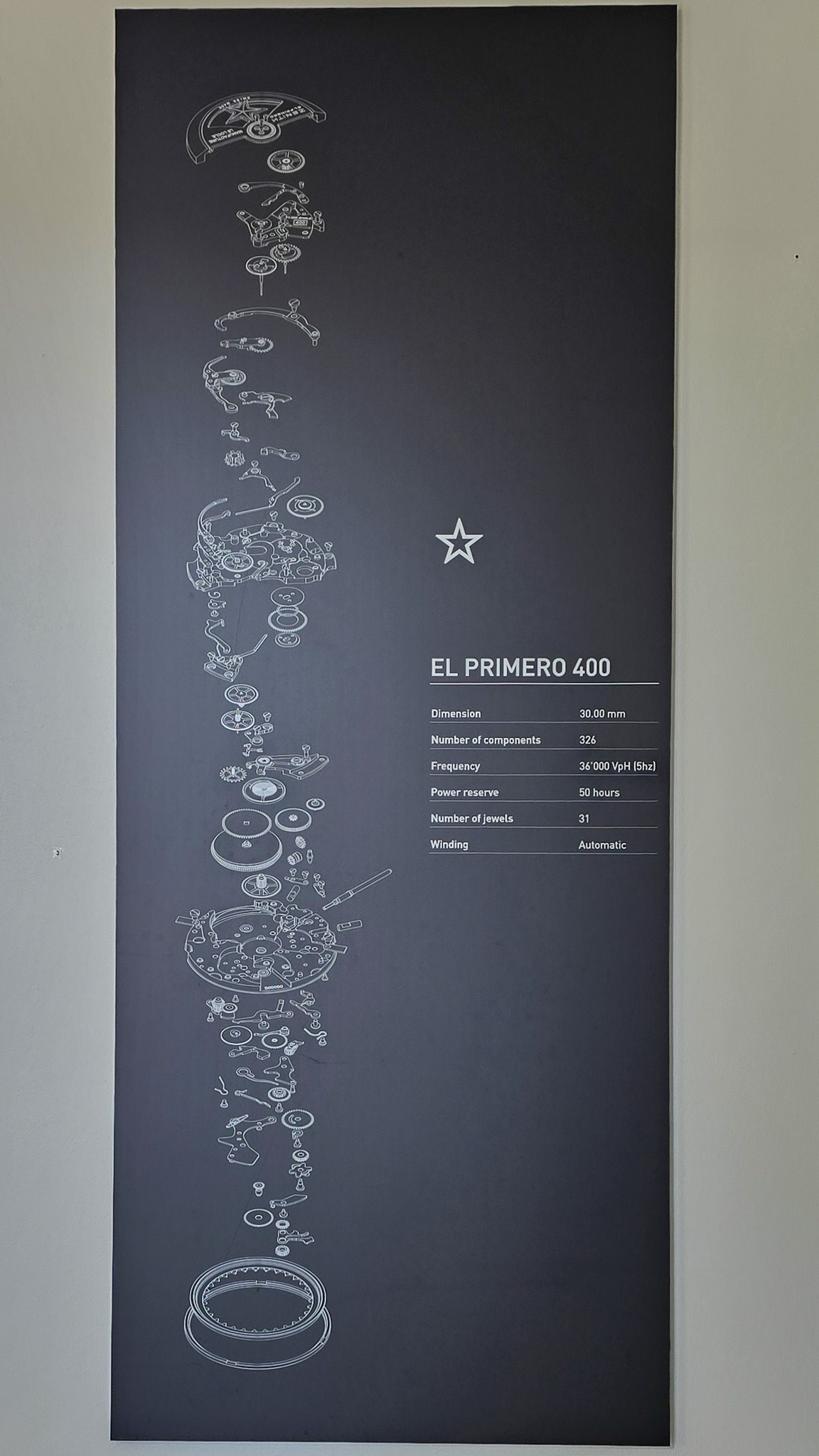

This is then followed by movement assembly, covering all manner of El Primeros, Elites , the modern re-interpretation of the Calibre 135, all the way to the Minute Repeaters. With the number of movement components ranging from the Elite 679’s 126, all the way to the El Primero’s 326, this team methodically brings to life, the beating heart of each Zenith timepiece. Each assembly of course going through regulation before moving on to the next stage.

The regulated movements proceed to have the dials & hands applied and then encased. Whilst the previous two stages require method & accuracy, there is a certain personal touch, some might say intimacy, at the third stage. A case in point – some Zenith watches sport a domed crystal, and to ensure legibility, some of the hands of those models are bent by hand.

Speaking to Madame Pascale, who was in the process of applying a bend on the hands of a Zenith Pilot Type 20 Chronograph, she remarked that she can tell if she did the hands of a specific piece or whether it’s her colleague adjacent, due to the ever so slight difference in the way that they apply the bend. Same effect but different enough for the experts to know; the fact is quite astonishing. A personal touch in a constant flow of watches. I think therein lies Zenith’s strength, despite all the modern machinery, the people and their craft continue to give life to its pieces.

Hands on with a legend

After a spot of lunch, the latter half of the afternoon was dedicated to a session in the Watch Clinic. We arrive at the clinic hall faced with various components – dials, cases, movements even bracelets & straps. The day’s challenge was very specific and came in two exercises. First, was disassembling and re-assembling an El Primero clutch. Armed with tweezers and screwdrivers, we set about under Romain’s guidance. A component that’s no bigger than a 3rd of a 5 pence coin looked life-like under my loupe as I went about the disassembly and re-assembly. And I have got to say, the re-assembly was quite a test of my focus and dexterity!

Challenge number two had us tinkering with the gears, making adjustments and finding the optimal gear contact ratio. Too tight and the movement seizes, too loose and the load is not shared optimally which leads to increased wear, and reduced accuracy. Thanks to the way that the El Primero movement has been engineered and the expert tuition from Romain, it was easy enough to find where I need to make the adjustments from, leaving me with judging the right position that allows for the optimal results. Happy to say that I passed both challenges, albeit my hands could probably do with a bit of lightness in its action!

Having Zenith as my first manufacture tour sets a solid foundation and a high benchmark. As it celebrates its 160 years in watchmaking, it continues the legacy left by Georges Favre-Jacot. A brand that has richness in heritage yet continues to push forward into the future. It is a brand I have long thought highly of, largely because of the legend of the El Primero. However, this visit gave me a renewed perspective and greater appreciation of what it truly stands for & what it represents in watchmaking.

If you’re planning a trip to Switzerland and love things horology, I couldn’t recommend enough going to a Zenith Manufacture tour. You can find more information on how to book a visit via their website (click link here). It is a unique blend of history talks, behind the scenes look and opportunities to have a go at tinkering with these mechanical wonders. It is a watchmaking pilgrimage that is certain to leave an impression and an appreciation of both the past, the present and the future of Swiss watchmaking.

“But wait, what about the Attic?” I hear you say. We’ll cover that for another day, for it’s a story that deserves to be remembered, told and honoured, many times over, thanks to the will of one man and his colleagues.

Leave a Reply